A team of engineers from the National University of Singapore (NUS) recently discovered that a naturally occurring bacterium, Thermoanaerobacterium thermosaccharolyticum TG57, isolated from waste generated after harvesting mushrooms, is capable of directly converting cellulose, a plant-based material, to biobutanol.

Traditional biofuels are produced from food crops. This approach is highly costly and competes with food production in the use of land, water, energy and other environmental resources.

Biofuels produced from unprocessed cellulosic materials such as plant biomass, as well as agriculture, horticultural and organic waste, are expected to meet growing energy demands without increasing greenhouse gas emissions resulting from the burning of fossil fuels. These cellulosic materials are in great abundance, environmentally friendly, and economically sustainable.

Among various types of biofuels, biobutanol offers a great promise as petrol substitute because of its high energy density and superior properties. It can directly replace gasoline in car engines without any modification. However, commercial production of biobutanol has been hampered by the lack of potent microbes capable of converting cellulosic biomass into biofuels.

The novel technique developed by the NUS team could potentially be a game-changing technology for cost effective and sustainable biofuel production.

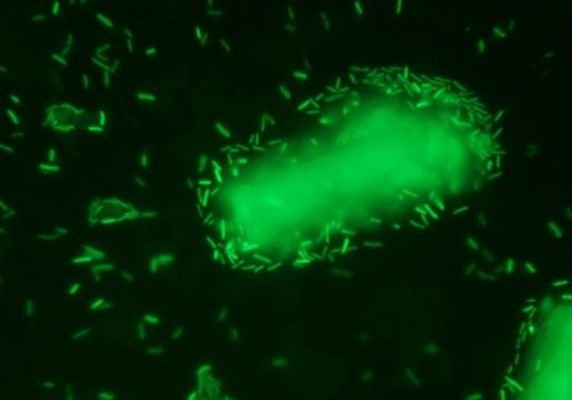

Spent mushroom compost — typically composed of wheat straw and saw dust — is the residual compost waste generated by mushroom farming. The microorganisms in the waste are left to evolve naturally for more than two years to obtain the unique TG57 strain.

The fermentation process is simple, and no complicated pre-treatment or genetic modification of the microorganisms is required. When cellulose is added, the bacterium simply digests it to produce butanol as the main product.