At the Biomaterials and Tissue Engineering Laboratory in IIT-Guwahati, Dr Biman B Mandal has been working with silk proteins to try and create an artificial implant that mimics the architecture and structure of real tissues, organs, bone, and cartilage.

Mandal and his team of researchers have created prototypes of bone, cartilage, and knee-meniscus — structural tissues. Soft tissues like liver, heart and skin tissue have also been printed with the bio-ink successfully by the team, which is now awaiting patent certificate for the Muga silk protein bio-ink.

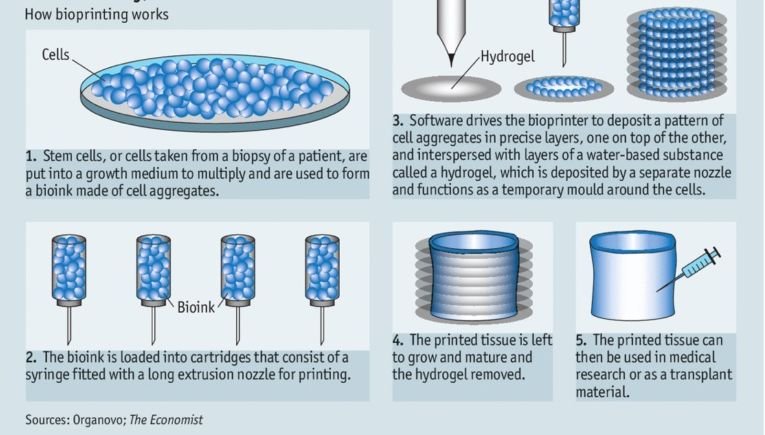

To begin with, a virtual 3D model of the organ /implant is constructed using MRI and CT scans to match the patient’s exact requirement. The Muga silk bio-ink is then incorporated with stem cells from the patient before the artificial tissue is printed.

The tissue or organ is then matured in a laboratory (the stem cells are programmed to specialize/differentiate and form all the different cell types in an organ/tissue) before it is implanted to take the place of a defective body part.

Once implanted, the mature stem cells in the 3D printed patch continue to grow and proliferate, Meanwhile, the silk protein degrades into amino acids, facilitating the regrowth of damaged parts of the organ

The technology could go a long way in reducing the wide gap between patients in need of organ transplants/implants, and the dearth of healthy donors.

Reference- Firstpost, The Print,