A new technique for cooling solar panels has been under development in Egypt. A mixture of water, aluminum oxide ((Al2O3)), and phase change material (PCM) calcium chloride hexahydrate (CaCl2H12O6), cools the PV modules from underneath.

The scientists from Egypt’s Benha University applied various mixtures of their passive coolants to a 50 W polycrystalline PV panel and compared performance during summer months in Cairo with that of an untreated panel.

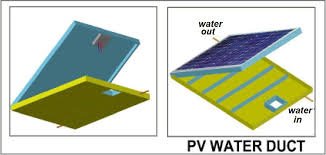

A cooling unit, DC pump, valves, water flow meter and connecting pipes provided a system with aluminum channels underneath the panels for the water and the Al2O3/PCM mixture. The panels were south adjusted and oriented 30 degrees from horizontal.

The PCM mixture was heated to melting point to form a liquid and Al2O3 nanoparticles were added to it in the aluminum channels. “The dispersion of particles in the PCM liquid is done using an agitator bath with four different mass concentrations,” the group stated.

The researchers said a mixture of water and the Al2O3/PCM liquid outperformed the use of water alone and the best performance from the panels were recorded using 75% water and 25% Al2O3/PCM.

A similar technique, using CaCl2.6H2O–Fe3Cl2.6H2O eutectic as a phase change material, was recently proposed by scientists from India’s KPR Institute of Engineering and Technology and the National Engineering College.

Reference- PV Magazine, Journal Renewable Energy, Benha University, Clean Technica, ScienceDirect website