Batteries might be far better for the environment than fossil fuels, but they need disposing of at the end of life, so solving this issue in a eco-friendly manner will really usher in the green revolution that batteries promise.

The mining and refinement of raw materials is estimated to contribute 30 per cent of a battery’s greenhouse gas emissions.

The Swedish battery manufacturer Northvolt, a company founded by two former Tesla executives in 2016 aims to solve this issue by : recycling. They aim to retrieve the raw materials from a spent battery and reuse them for a new one.

Right now, the recycling of electric car batteries is a complex and technical undertaking. It’s very expensive to do this in a safe way, and it is very time demanding.

Once a battery has been safely delivered to Northvolt’s recycling centre, the process of dismantling and discharging takes place. The problem is that batteries have a tendency to go boom if disassembled incorrectly.

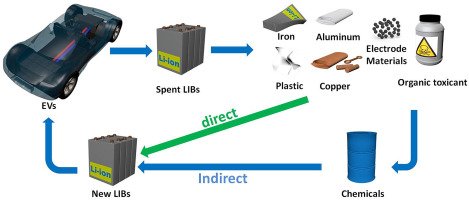

After the battery has been safely dismantled and the cells and modules retrieved, Northvolt begins to crush those cells in an air-tight vacuum, ensuring that there are no reactive gases like carbon dioxide and oxygen around to contaminate the materials in the cells.

As soon as all the crushed material has been sorted and separated based on density, magneticity and size, all that remains is a pile of black powder, something that Nehrenheim calls “black mass”.

The powder is made up of nickel, manganese, cobalt, lithium hydroxide and graphite – some of the most crucial components in a lithium-ion battery.

This powder undergoes something called a hydrometallurgical process, where the black powder is effectively dumped into an acid bath.

All those raw materials will be separated from the black powder, leaving behind all the ingredients needed to make a new electric car battery.

Such a breakthrough in recycling, if it can be scaled, would be huge in tackling the climate crisis. The project has been operational since the summer and is already producing sample cells.

Come 2030, Northvolt hopes that 50 per cent of the raw materials that it uses to make its batteries will come from recycled material, by which point it aims to have 25 per cent of the European market.

This is a PRNewswire Feed; edited by Clean-Future Team