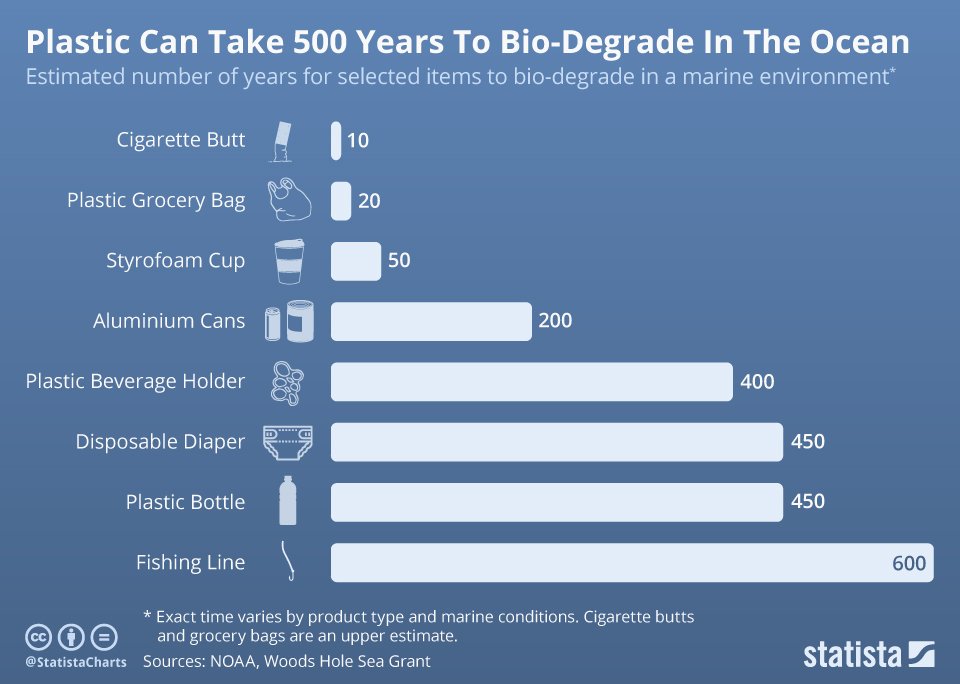

Plastics are one of the world’s largest polluters, taking hundreds of years to degrade in nature. Efforts to shift from petrochemical plastics to renewable and biodegradable plastics have proven tricky — the production process can require toxic chemicals and is expensive, and the mechanical strength and water stability is often insufficient.

But now a research team from the University of Maryland and Yale School of the Environment (YSE), has created a high-quality biodegradable plastic from wood byproducts that they hope can solve one of the world’s most pressing environmental issues.

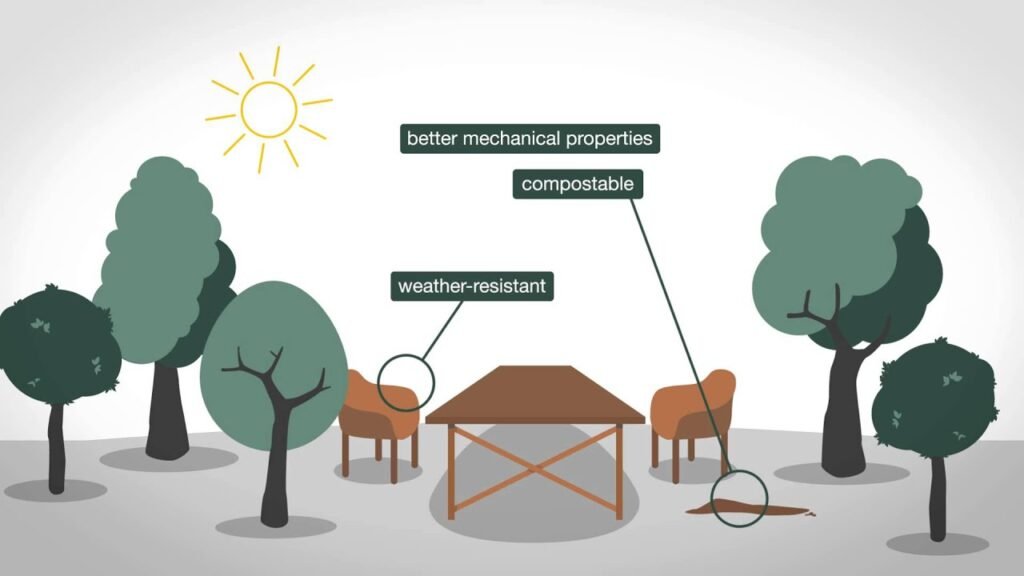

The published study outlines the process of deconstructing the porous matrix of natural wood into a slurry. The researchers say the resulting material shows a high mechanical strength, stability when holding liquids, and UV-light resistance.

It can also be recycled or safely biodegraded in the natural environment, and has a lower life-cycle environmental impact when compared with petroleum-based plastics and other biodegradable plastics.

To create the slurry mixture, the researchers used a wood powder — a processing residue usually discarded as waste in lumber mills — and deconstructed the loose, porous structure of the powder with a biodegradable and recyclable deep eutectic solvent (DES).

The resulting mixture, which features nanoscale entanglement and hydrogen bonding between the regenerated lignin and cellulose micro/nanofibrils, has a high solid content and high viscosity, which can be casted and rolled without breaking.

The research team then led a comprehensive life cycle assessment to test the environmental impacts of the bioplastic against commons plastics.

Sheets of the bioplastic were buried in soil, fracturing after two weeks and completely degrading after three months; additionally, researchers say the bioplastic can be broken back down into the slurry by mechanical stirring, which also allows for the DES to be recovered and reused.

One area the research team continues to investigate is the potential impact on forests if the manufacturing of this bioplastic is scaled up.

Reference- SciTech Daily, Journal Nature Sustainability, Yale School of the Environment (YSE) Media Outreach