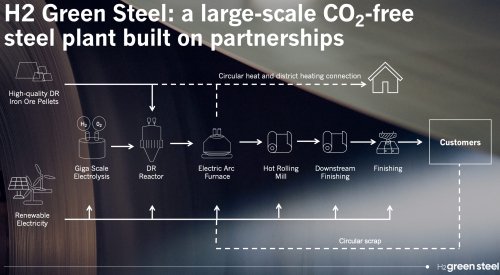

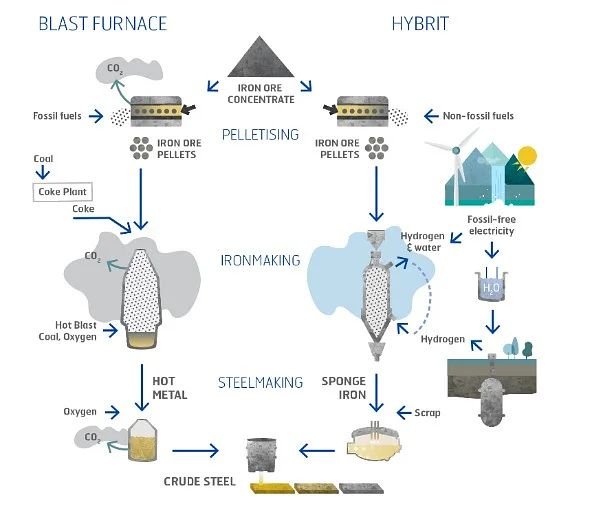

HYBRIT and H2 Green Steel have begun initiatives in Sweden with the goal of producing 10 million tonnes (mt) of fossil-free crude (green) steel per year by 2030.

To manufacture green steel, green hydrogen is required; to manufacture green hydrogen, inexpensive renewable energy is required. According to HYBRIT and H2 Green Steel, this will be accomplished using wind energy for a levelized cost of energy of $30 per megawatt-hour. With renewable energy prices continuing to decline, it seems possible that they will be able to do this.

When you combine the rising cost of carbon with the push to decarbonize, you have a winner. Carbon credits worth around $85 per tonne are likely to be made available to green steel companies.

Sweden is a very minor steel manufacturer, and this objective of 10 million tonnes is three times what the Scandinavian nation now produces. “However, the nation has Europe’s greatest iron ore deposits and outstanding renewable energy supplies – two critical conditions for the manufacturing of green hydrogen and decarbonized crude steel.”

Another component of the green steel mix to consider is the technique used to generate green hydrogen — in this instance, alkaline electrolysis technology.

Costs connected with this are predicted to half by 2030, resulting in a leveling cost of $1 per kg of green hydrogen produced utilizing onshore wind energy. Global interest is expected in this emerging field of climate change mitigation.

Reference- Mining.com Article, Clean Technica, HYBRIT website, H2 Green Steel website