Old solar panels contain silicon, which can be recovered and processed to make new solar cells, according to a news release from Fraunhofer ISE, one of Germany’s finest scientific organizations.

Recycled solar modules contain an estimated 10,000 tonnes of silicon per year in Germany. By the year 2029, that number will climb to several hundred thousand tonnes a year. There is currently no reprocessing of the silicon solar cells in the modules that have been discarded.

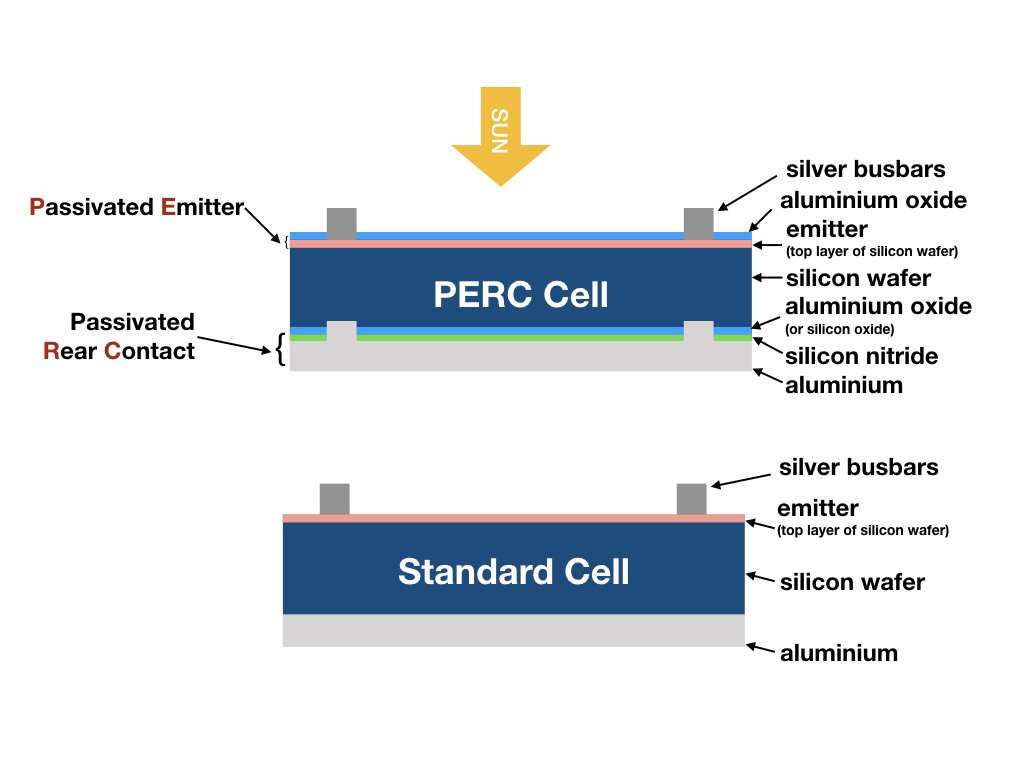

Researchers at Fraunhofer ISE have devised a method for industrially reprocessing silicon from rejected modules and repurposing it in the production of new PERC solar cells. Solar cells rely heavily on silicon as their primary material. It is now feasible to recycle any crystalline silicon photovoltaic modules, independent of their manufacturer or place of origin, using a brand-new method.

Byproducts of mechanical recycling are used to separate and collect solar cell fragments. Sorting techniques first break down the cell fragments into smaller pieces of 0.1 to 1 millimetre in diameter, which may then be used for further research.

Wet chemical etching is used to remove the emitter and silver connections from the silicon’s backside, as well as the anti-reflective layer. Ingots and wafers are made from the cleansed silicon after it is processed into monocrystalline and quasi-monocrystalline ingots.

No commercially available ultra-pure silicon is used to crystallise the recycled silicon in this Fraunhofer ISE process. The solar cell conversion efficiency was 19.7% in the first attempt.

It falls short of the 22.2% efficiency of today’s top-of-the-line premium PERC solar cells. Despite the fact that Fraunhofer ISE recycling process is a relatively new technique, improvements in the system will undoubtedly improve the performance of the recycled silicon in the future.

This is a Globe PR Newswire; edited by Clean-Future Team