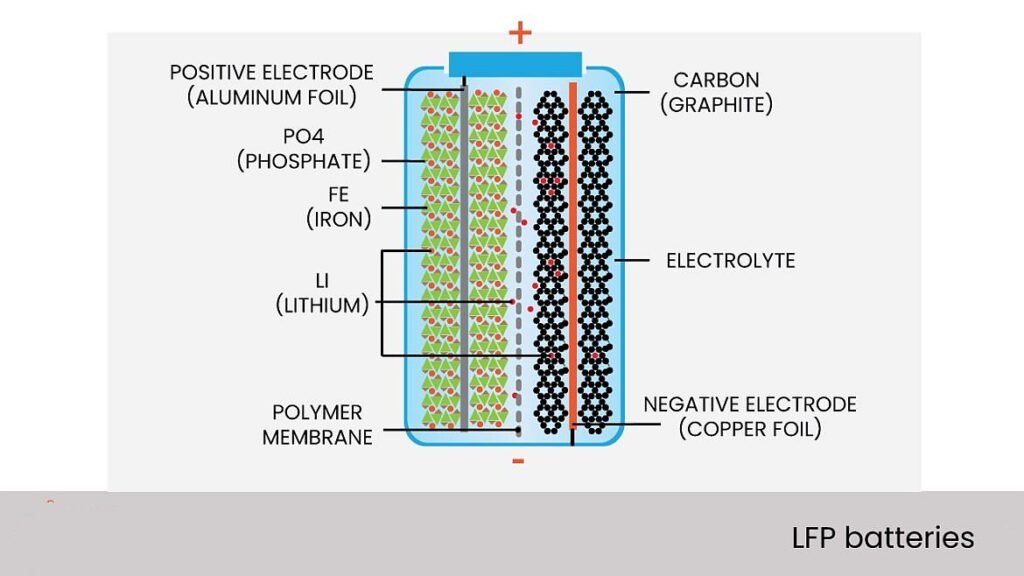

LFP (lithium iron phosphate) batteries may not have the energy density of cobalt and nickel batteries, but they do have one significant advantage: the raw ingredients required to create them are plentiful, affordable, and available in practically every country on the planet. As a result, they are typically less costly.

Today, nickel prices have skyrocketed to absurd new highs as a result of the Russia-Ukraine crisis, exposing the cost difference between LFP and conventional batteries even more. Increased nickel costs have already prompted automakers to boost the prices of several EVs presently on the market. Nobody can afford to rely on labor or resources that may become unavailable as a result of military conflicts or political restraints.

A Chinese company, Gotion High Tech, intends to begin production of an LFP battery with an energy density of 230 Wh/kg by the end of this year. Similar batteries with an energy density of 210 Wh/kg are already in production. In comparison, the energy density of today’s cobalt and nickel-based cells is roughly 250 to 270 Wh/kg.

SVolt, another startup, has hit the 200 Wh/kg barrier with its own LFP batteries and intends to reach 230 Wh/kg by next year.

While NCM will continue to be utilized in some applications where high energy density is critical, such as premium electric sport vehicles, the cobalt-free battery technologies NMx (LNMO) and LFP (LiFePO4) are expected to power most mainstream electric cars.

Reference- Gotion High Tech website, SVolt website, PushEVs Article, Chinese news source Gasgoo