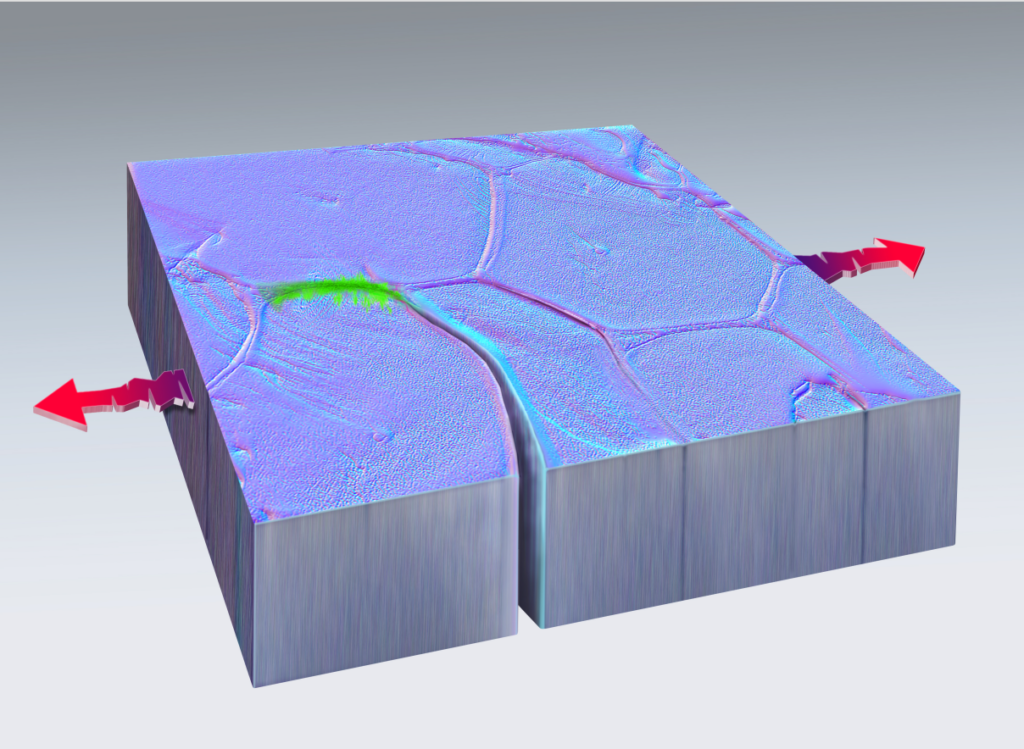

The scientists at Texas A&M University were surprised to observe a piece of metal repairing itself despite the usual wear and tear that machines experience over time. The researchers observed how a 40-nanometer-thick piece of platinum could repair itself while being pulled in a vacuum 200 times per second using an electron microscope.

This recent discovery has revealed that metals possess the capability to self heal, specifically when it comes to repairing small fractures at the nanoscale caused by fatigue. If we are able to understand and utilize this ability, it could have significant implications.

Researchers are stating that for the firs time they have observed a metal fragment breaking and then rejoining without any external intervention, which is an intriguing discovery. This occurrence has the potential to bring about significant advancements in engineering, although finding a means to utilize it effectively remains a challenge.

Various structures, such as electronic devices, vehicle engines, bridges, solar panels, and wind turbines, often fail unexpectedly due to repeated stress, resulting in cracks and eventual material breakdown. This leads to significant financial losses, amounting to billions of dollars annually.

If we can figure out how to utilize the “crack flank cold welding” phenomenon, it would result in significant cost and emission savings. However, it will be challenging to find methods to harness this self-repairing capability. There are still many uncertainties and it is uncertain whether these discoveries can be applied universally.

Reference- Journal Nature, Texas A&M University PR, Interesting Engineering, Futurism