The shift towards green energy will need a large amount of raw materials, and nickel will play a crucial role in making this transition possible. By 2030, nickel will remain a crucial component in electric vehicle batteries, comprising approximately 50% of the worldwide market.

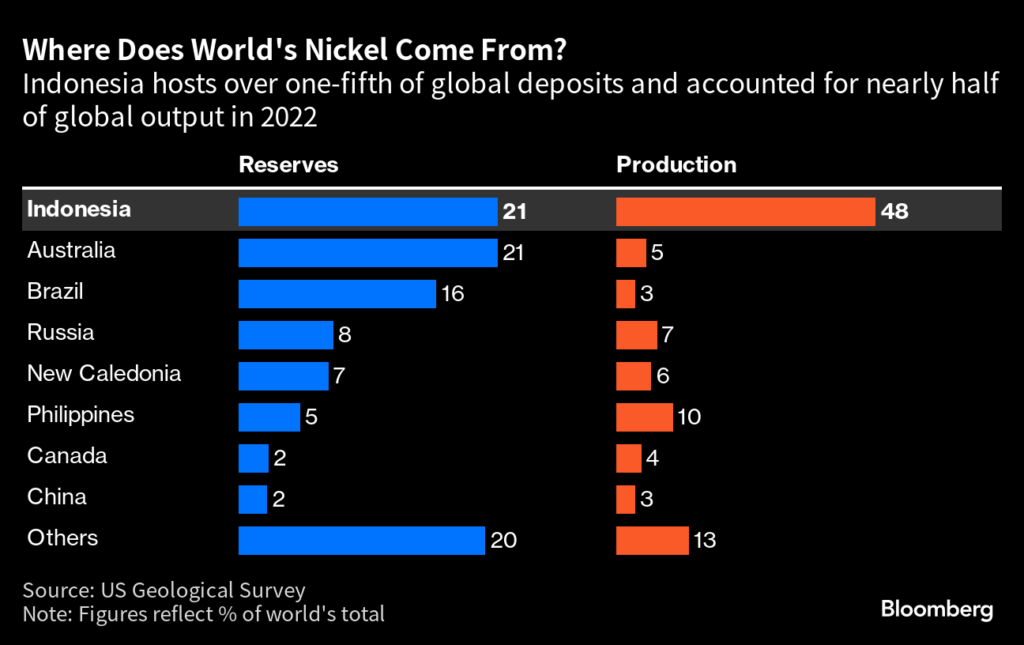

Indonesia will be the primary source of supply, contributing 60% of global nickel mined output and 40% of refined output by that time.

Currently, the popular high-nickel chemistry used in batteries contains 0.66 kg of nickel per kilowatt-hour (kWh). However, there are emerging alternative chemistries with lower nickel content. It is predicted that by 2030, nickel-containing chemistries will make up approximately 50% of the global market.

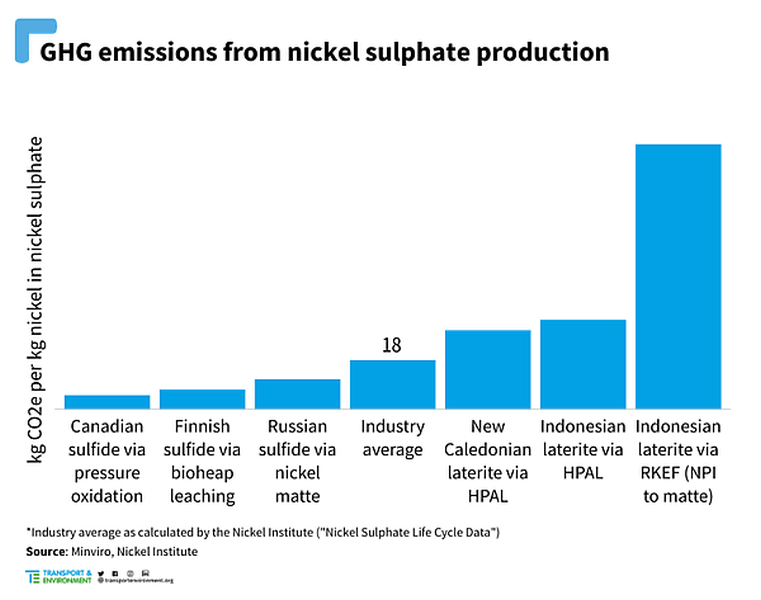

Nickel mining and refining have a significant impact on the environment in terms of carbon emissions, but there are ways to reduce this impact. The amount of greenhouse gases emitted during nickel sulphate production differs greatly depending on factors such as the energy source and production methods used.

According to Minviro’s analysis, operations that have access to renewable energy and use hydrometallurgical technologies like bioheap leaching and pressure oxidation have the smallest carbon footprint.

The best nickel sulphate production facilities in Canada and Finland have emissions levels that are 70% and 63% lower, respectively, compared to the industry average.

When processing laterite ores into nickel pig iron (NPI) to matte to nickel sulphate, the emissions generated are five times higher than the industry average. Similarly, the high pressure acid leaching (HPAL) method, which is gaining popularity in Indonesia, produces almost twice as many emissions as the industry average.

Research indicates that the adoption of renewable energy for electricity can lead to an average reduction of emissions by 40%. In addition, the industry can further mitigate greenhouse gas emissions by employing

- zero-carbon chemicals,

- decarbonizing mining vehicles,

- improving logistics, and

- implementing more energy-efficient ore processing techniques such as bioheap leaching and pressure oxidation for sulphides. Laterites can be processed using heap leaching and atmospheric hydrometallurgical processing methods.

To ensure cleaner production of nickel, policies are necessary. These policies should involve increasing the use of renewable energy, establishing cleaner methods of refining and processing nickel, and implementing the use of the most advanced technologies for waste management and biodiversity preservation.

Applying strong standards like Responsible Mining Assurance (IRMA) to a greater number of mining sites worldwide will enhance environmental and social responsibility.

Reference- Transport & Environment – Briefing & Executive summar, Bloomberg