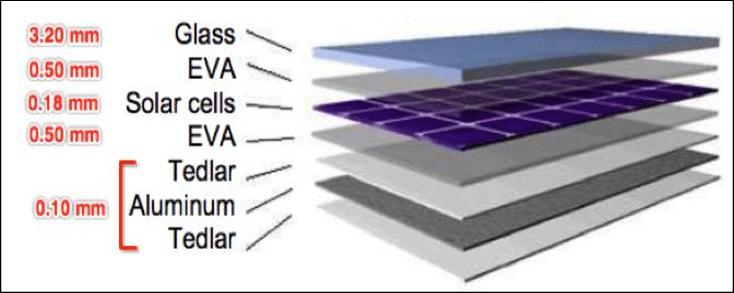

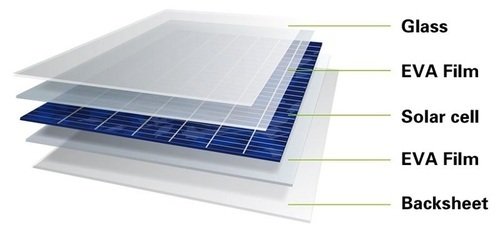

One of the most critical constituent materials used in the construction of a Solar PV module is the backsheet. This is the outermost layer of the PV module placed at the non-sunny side of it.

While this sheet contributes only 4-5 % of the total cost of a solar panel, the criticality is quite high compared to its cost contribution. High quality backsheet will ensure solar panels’ longevity and ability to survive very difficult environmental conditions for 25 long years.

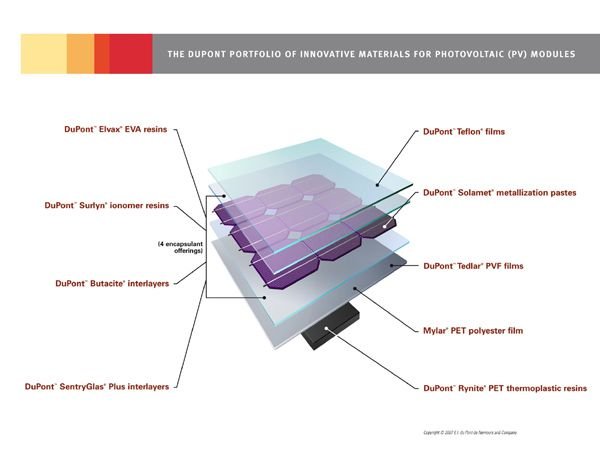

This is basically a polymeric laminate that protects the PV module from UV rays, moisture and other weathering aspects along with guarding as an electrical insulator.

Thus it should have the superlative properties of protection against moisture ingress, weatherability, mechanical strength, adhesion, dielectric properties, reflectivity etc. or an optimized balance of all of these.

Generally, the sheet is a three-layer laminate but there are lot of varieties available in the market be it the basic protective layers like flouride-based polymers, polyesters, polyamides, polypropylene etc. or thickness or combination of layers.

Till decade and half back, Tedlar was the only choice for protective layers of backsheets for solar modules – and it is still the only polymer that has proved its long-term (25 years or more) reliability in the field.

A wrong choice of backsheet can lead to severe adverse effect on modules and its very early failure due to backsheet’s cracking, yellowing and delamination etc.

This is a Businesswire Feed; edited by Clean-Future Team