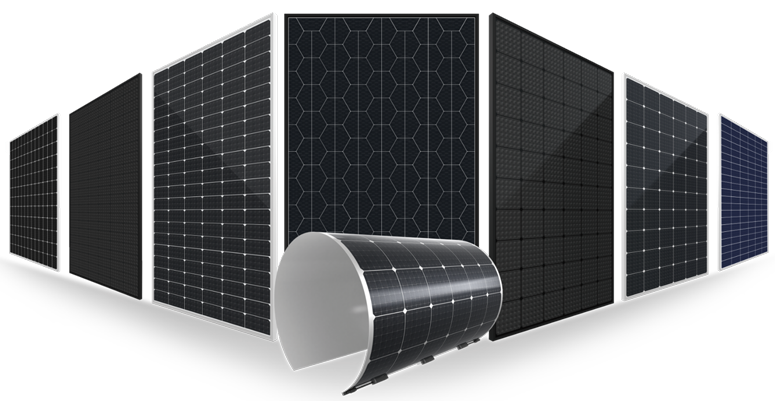

The world’s first manufacturer on GW-scale for MWT ((Metal Wrap Through) PV module, Sunport Power announced recently that the company has optimized the S6 flexible module product which aims the growing building integrated photovoltaic (BIPV) market.

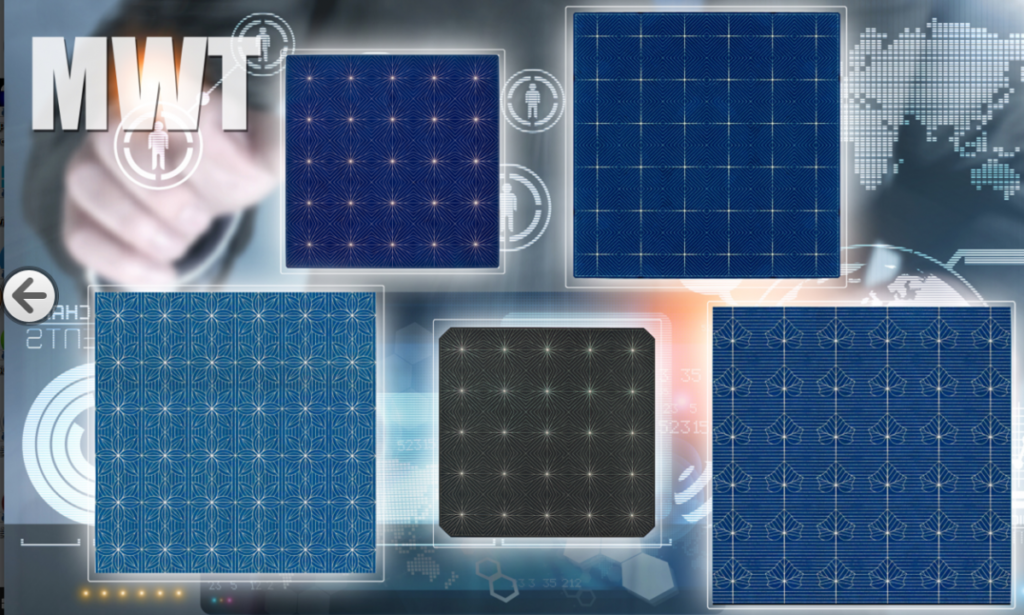

The MWT is an advanced back contact technology to increase solar cell and module efficiency by eliminating the busbar on the front side, and deploy both positive and negative electrodes on the rear side.

Compared to conventional module, the power yield of MWT products increased by 3% and around 15W more output.

Being launched in 2018 and later achieved successful production on pilot line, S6 was continuously upgraded and optimized by Sunport Power’s R&D team with its flexibility and high-efficiency for customers’ needs in different scenarios.

The module efficiency of 21.2% has been achieved by the new upgraded S6 module. With the booming of building integrated photovoltaic (BIPV) market, Sunport Power has received orders from multiple overseas customers in Europe, Japan, Australia, etc.

The silicon-based flexible module is only 4 kg in weight and 1.4mm thick, compared to a conventional PV module 19 kg in weight and 35-40mm thick.

This makes S6 especially suitable for application of BIPV which requires strict specifications of weight in many scenarios, such as roof, wall, sunshade, etc.

The newly developed S6 module honored certificate by TUV. The first year degradation is less than 2% and linear power output will be guaranteed above 82% within 25 years, the warranty re-insurance is provided by Lloyd’s, covering global market.

This is a PRwire Feed; edited by Clean-Future Team